In this case study, we are illustrating how the Engon team was able to upgrade the functionality and overall aesthetics of a product in the industrial and heavy equipment industry. Engon worked with the Client to fill a key gap in their product portfolio – the Client was missing high revenue products in their offerings, due to which their competition had a bigger market share.

Let’s dive in!

Services Employed:

Industry Served:

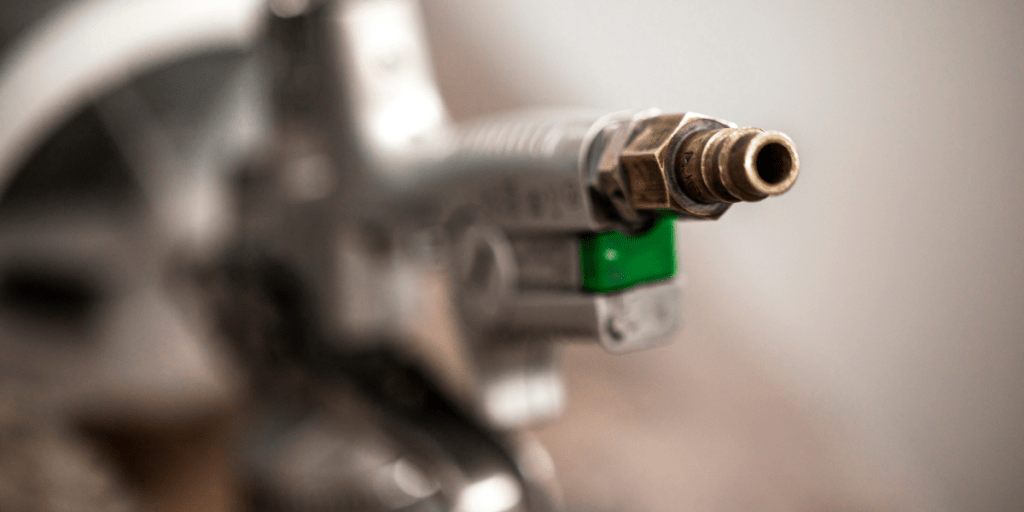

About the Air Nozzle

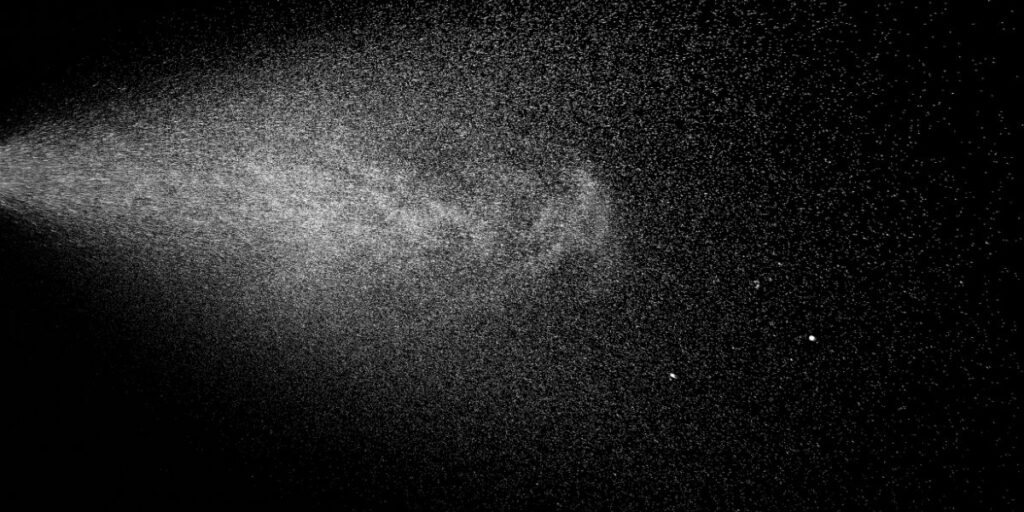

Air nozzle is a device used to disperse air or steam in a targeted manner. The air nozzles in our project had a flat fan or solid stream spray pattern. Due to its flat shape, the sound level and air consumption of such nozzles are very low when providing a strong blow off force. These air nozzles are used to blow off materials heavier than the usual liquid or dust.

How ENGON employed Product Engineering to Optimize the Existing Air Nozzle

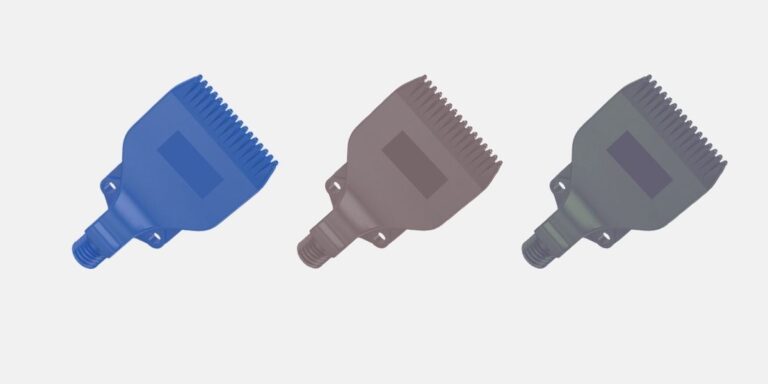

By benchmarking against the competition – the Client’s direct competitors, as well as similar products globally – we determined our focus to be on the overall aesthetics of the product. Our emphasis was to improve the look and feel of the product, while improving its technical performance.

We conducted surveys and discussions with the Client sales teams to gain insight into their target customer psyche. The results pushed us to focus on upgrading the product better than the competition. Our product engineers were able to solve engineering problems, as we started optimizing the design, and getting into DFM by understanding the manufacturing processes involved.

The results were clear. Our upgraded design filled the gap in the Client product portfolio. The chosen materials were more suitable for the manufacturing process, and we were able to reduce the time-to-market race with the new product while optimizing its technical performance.

Conclusions

Design for manufacturing intent

Thanks to the team’s incredible understanding of the manufacturing process, we were able to avoid hurdles in the production stage of the project. We were able to engineer air nozzles that are more energy efficient as compared to the competitor nozzles. With extensive reverse engineering, we were also able to achieve lower noise levels.

Successful prototyping and testing

We discovered conventional gaskets can not be used in the newer and improved version of the product, so we provided innovative solutions to the Client. By prototyping, we were able to validate the design of the product. We then shared our prototypes with the stakeholders, such as sales team, to get real-time feedback and further optimize the overall design of the product.

Such due diligence and smart performance of the Engon team has garnered trust and reliability in the industry as the engineering outsourcing partner for businesses worldwide. Choose us to obtain the best customized solution for your project.