This case study gives an insight into how the Client and Engon teams worked together to introduce an existing product in a new market. The existing product, aka, the Ladle Cart, had to be modified to become fully compatible with DIN standards so as to be able to enter the German (European) market successfully.

Let’s dive in!

Services Employed:

Industry Served:

About the Ladle Cart

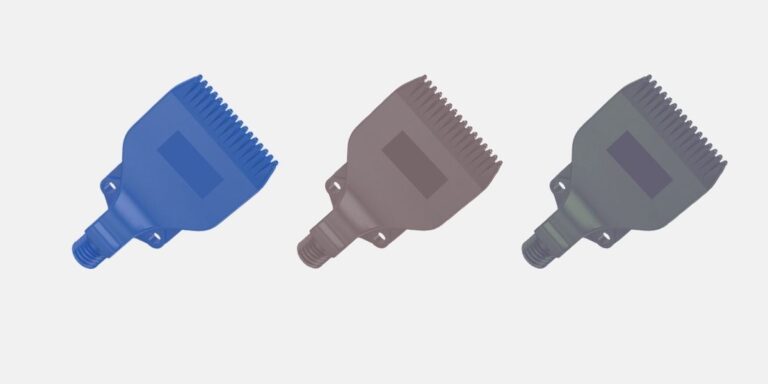

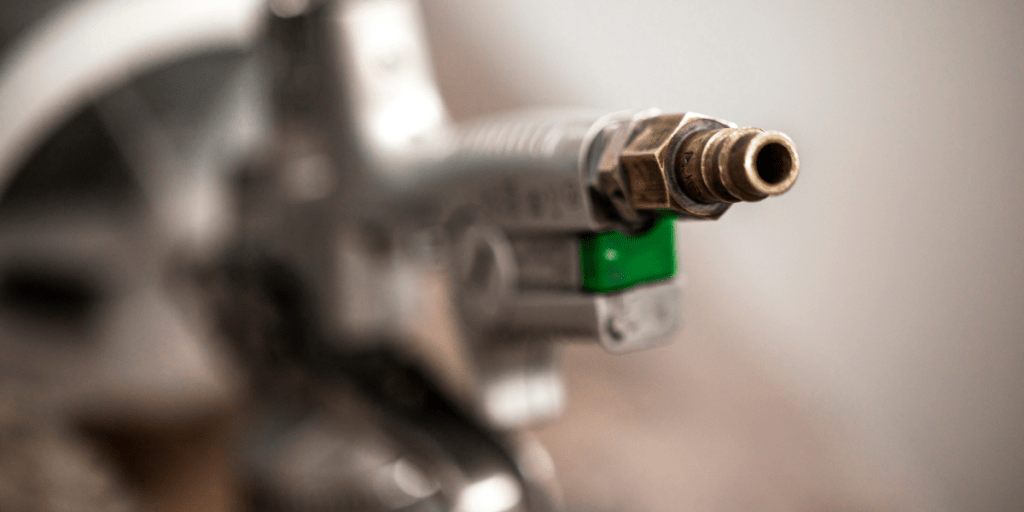

A ladle cart is a type of vehicle which is used to collect hot molten iron alloys, mild steel, and various alloys of steels in foundries. It can have a customized load capacity from 1 ton to 1,000 tons. The transfer cart is designed to resist high temperatures and to work continuously for all 7 days a week. Heat insulation material is used in the body of the cart to avoid the influence of high temperature on the electric control, transmission parts and table. A software system is used to control and manage safety of the ladle cart.

About the Product Localization of the Ladle Cart

Ladle carts are used in extreme environments. In the heavy-equipment industry, if the ladle cart stops for just one hour, the company can lose up to 1000 tons of production. Engon was working with a Client whose Ladle Cart was successful in the North American region, but had to be modified as per DIN standards so that it could enter the German/European market. As such, the Engon team had to focus on their mechanical design and 3D modeling expertise to ensure a compliant product with a reduced time-to-market duration to conquer this new market as well.

How ENGON and the Client worked on localizing the modified Ladle Cart in the German market.

At Engon, we understand every foundry is unique, specific to their geographical location. Even when our Client had a product successful in the North American region, we had to focus on modifying the existing ladle cart to be compliant with the DIN standards of the European, specifically German, market, and dominate this new market. Armed with newer and better technology, we were able to upgrade the ladle carts to last longer, run safer and cost less money per tonne of metal melted.

Next, we had to work on localizing the modified ladle cart in the German market. Thanks to our cross-functional team of experts with their thorough understanding of standards, we were able to infiltrate the German market successfully. We worked with the Client in implementing the standards & solving challenges that it poses.

With such systematic implementation with part numbering system to create efficient subassemblies and assemblies, we were able to optimize the workflow, and implement seamless team communication for future design.

Conclusions

It’s been a non-stop localization process

Over the past two years, we have completed scores of localization and adaptation tasks, thus freeing up time for the client to deal with other priorities.

There’s more success when design intent is kept in mind

Design intent allows you to modify. Since one of the main goals of this project was to enter a brand-new market, the Engon experts were flexible to keep design intent in mind. Doing so helped reduce material usage, production time, and costs, thus adding more value to the product.

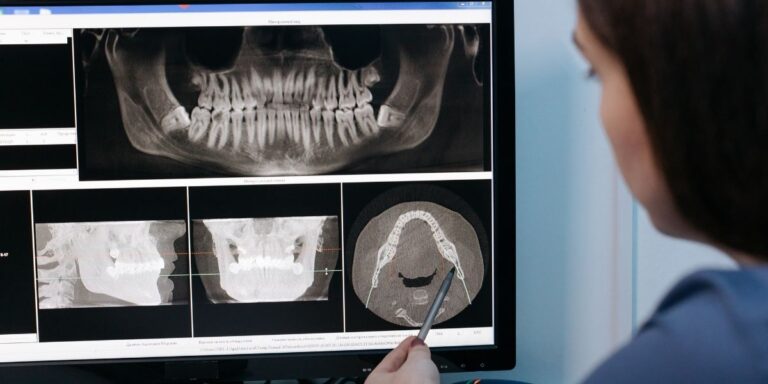

Our mechanical designers and 3D modeling engineers helped identify possible design flaws by analyzying the design through simulation software. Such careful design analysis led us to make the product more safer and durable, without compromising the quality of the ladle cart while getting it to the market.

Such due diligence and smart performance of the Engon team has garnered trust and reliability in the industry as the engineering outsourcing partner for businesses worldwide. Choose us to obtain the best customized solution for your project.