In this case study, we are sharing how Engon worked with a Client who was selling industrial chemical products to other businesses in bulk, but facing major issues with mishandling during transportation. The Client was also looking for ways to maximise savings during production and transportation, while enhancing the product to edge out the competition.

Let’s dive in!

Services Employed:

Industry Served:

About the Enhancement

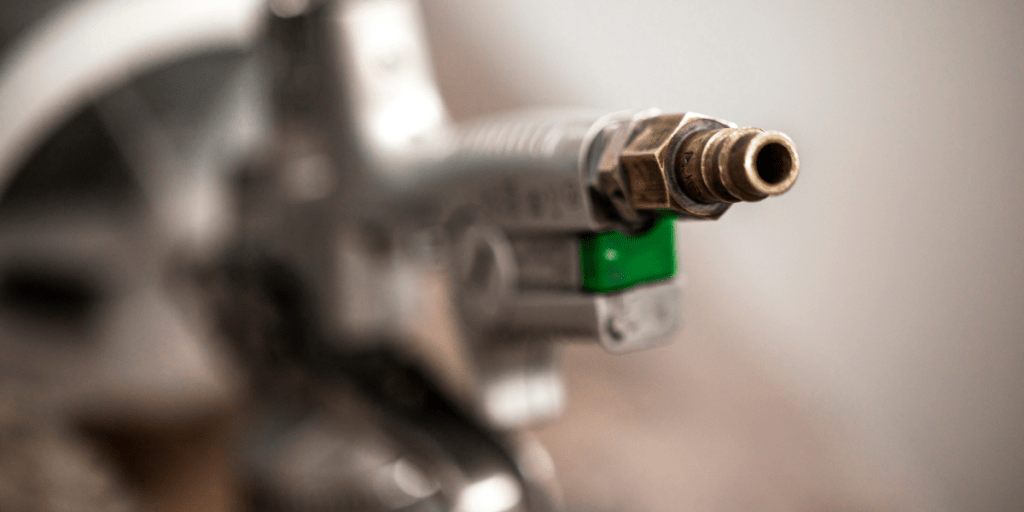

The existing packaging of the product was failing during transportation, thus resulting in unreliable delivery & financial losses. The Engon team started the project by testing the existing packaging and understanding root causes of the numerous issues. As a standard, we conducted benchmarking with global as well as domestic competitors to work on enhancing the aesthetics and branding points of the overall product itself.

How ENGON employed Plastic Engineering to Resolve Packaging Problems

Our focus was to engineer the whole packaging of the product to resolve the issues arising from transportation, and making it easier to handle and use these products, whether in the warehouse, en-route, or in use. The analysts and plastic engineers worked on the feedback given by the stakeholders who were handling these products at every stage of the product lifecycle.

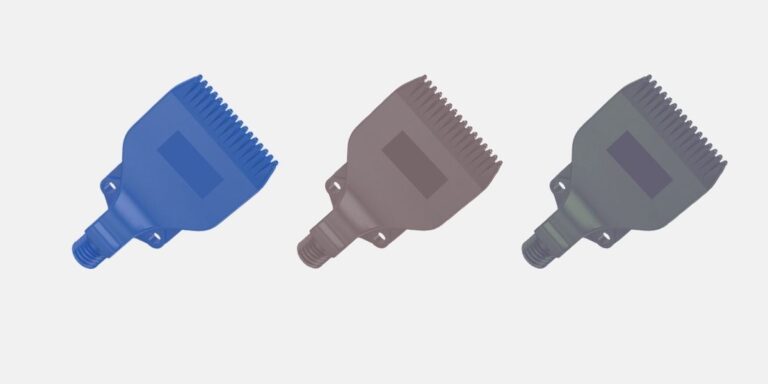

We were working to lessen the probability of failure. So we worked extensively in mechanical analysis and 3D modeling to validate the design.

With great efforts in plastic engineering, we were able to achieve 19% reduction in material used, setting new standards. This reduction was a result of the innovative tooling solutions we were able to provide due to our expertise in mold design. With such a reduction in material usage, we were able to bring down overall production costs as well. The new enhanced packaging was able to withstand long distances in transportation without rupturing. And human errors with stacking or dropping products did not automatically mean loss to the Client anymore.

Conclusions

Design for manufacturing intent

Our plastic engineers took complete ownership of the life cycle of the product. The product itself was working well. However, transportation and mishandling issues were affecting the Client a lot. With the new enhanced packaging, we were able to resolve the issues. Additionally, the Engon team was also able to distinguish the product from a crowd of competitors and improving brand recall.

Successful prototyping and testing

Prototyping the new packaging of the product helped in evaluating its technical feasibility. It also helped in determining if the materials used are durable and capable of withstanding the wear and tear of use. We were helping the Client to reduce financial losses from unreliable delivery as well as issues from transportation and mishandling. Thus, prototyping helped in testing the new enhanced packaging – we involved stakeholders in the testing to get real-time feedback.

Such due diligence and smart performance of the Engon team has garnered trust and reliability in the industry as the engineering outsourcing partner for businesses worldwide. Choose us to obtain the best customized solution for your project.