Mechanical Engineering & Design Services Trusted by US Businesses

At Engon Technologies, we deliver world-class mechanical engineering solutions tailored for American manufacturers, OEMs, and product innovators. From feasibility studies and systems analysis to design development and production support, we help US businesses accelerate product launches, cut costs, and improve performance.

Let’s Build Your Dream Project

We combine technical expertise with creative thinking to deliver solutions that match your goals. Start the conversation today and see how we can turn your vision into a winning project.

Proven Results for US & Global Clients

Product Design and Development Services

We deliver innovative Mechanical Engineering & Design Services that enhance product performance, improve efficiency, and drive long term business growth.

Cost

Optimization

Delivered substantial production savings for a US-based medical device company by managing the complete end-to-end tool design for their plastic engineering.

Swift

Execution

Reduced manufacturing time by 50% and mold costs by 30% for an OEM in Southeast Asia through high-efficiency double cavity blow mold design in close collaboration with their R&D team.

Smart

Performance

Cut engineering costs by 45% for an aircraft interior manufacturer by developing lightweight vacuum-formed products, reducing weight by 14%.

Intelligent

Workflow

Achieved 40% cost reduction for an automotive supplier by switching their product line to extrusion blow molding and optimizing the design of their entire product line.

Why Choose Our Mechanical Product Design Company?

Compliance with US Standards

Designs aligned with ASME, ANSI, ASTM, and ISO requirements.

Frugal Engineering

Speed, cost-efficiency, and market adaptability without unnecessary bureaucracy.

Reliable Delivery

From concept to execution, we deliver on time, every time.

Cross-Industry Expertise

Serving aerospace, automotive, consumer products, and industrial machinery.

Manufacturing Mastery

Deep understanding of processes ensures innovative, production-ready designs

Our Custom Product Design and Development Services

We offer a Complete Range of Mechanical Engineering Solutions for all your needs.

Product Engineering

Accelerate your design and development with our analytical and problem solving skills. With rich cross-vertical knowledge, our product engineers can create powerful products optimized by design-to-manufacture (DFM), design-for-assembly (DFA), and design-for-reliability (DFR) viewpoints.

Product Localization

Companies need to carefully curate and adapt to regional requirements when entering a new market. We offer product localization services like benchmarking, value analysis, detailed designing, prototyping and testing, to fit your product to the local market and meet product compliances for that market.

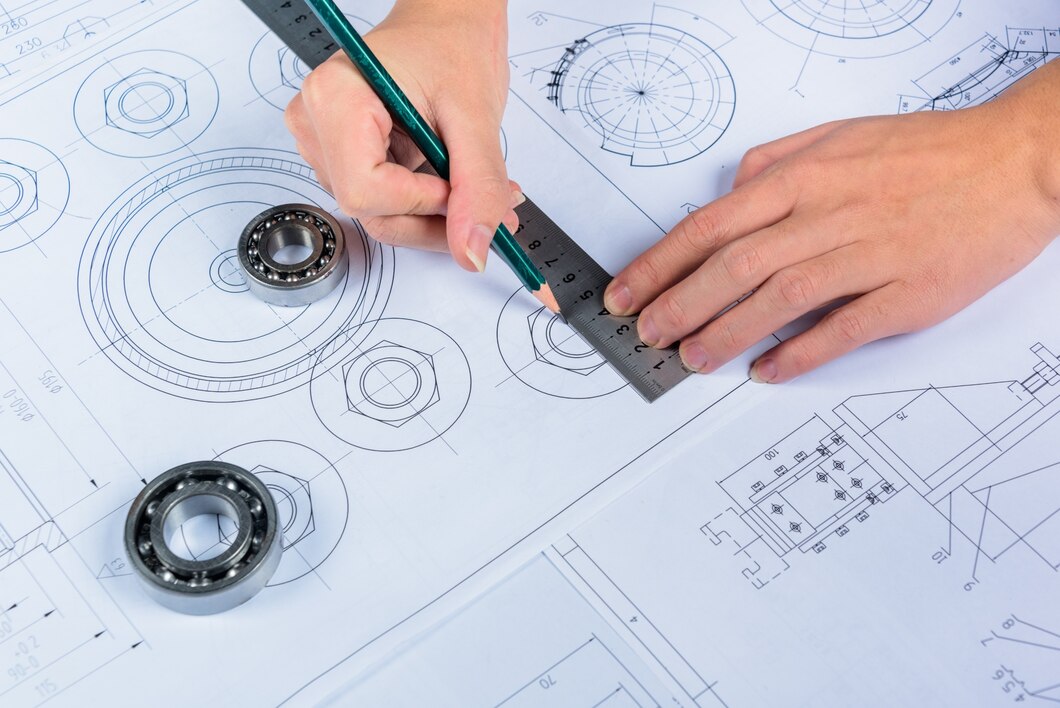

Mechanical Design

Our mechanical designers enhance both the accuracy and general safety of your product by verifying and validating the product design, thus ensuring more success in the market. We focus on each stage of the design cycle, starting from concept design till tooling. Our focus is on Design for Manufacturing and Assembly (DFMA).

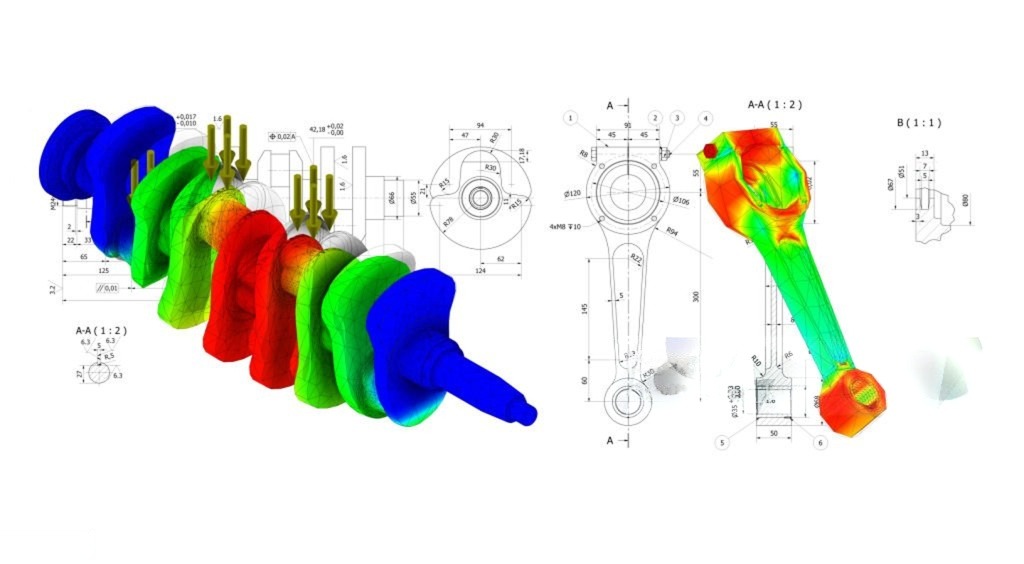

Mechanical Analysis

Ensuring safety is the primary reason for all mechanical analysis. And our specialists focus on structural, thermal, CFD, mold flow, electromagnetic and multi-body dynamics analysis to understand and ensure a cost-effective design. We analyze and optimize to give you better insights into your product, thus helping you take informed decisions.

Technical Illustration Services

We help you enhance the understanding of a complex idea with simple drawings or illustrations. Our work experience includes setting up simple product manuals for assembling furniture to complex manuals for aircraft assembly and maintenance. We focus on conveying accurate graphical information to the intent.

3D Modeling Services

Your project requires design efficiency and our engineers let you explore the physical aspects of a design with exploded views, layout drawings, design validation and verification, and more, without surrendering to physical limitations. Our expertise is proven to take you faster to market.

Engineering Drafting Services

Each department or stakeholder has their own intent, and it is imperative to convey information with the right technical drawing. We can convert original AEC drawing into an accurate illustration as per AIA, DIN and other international standards.

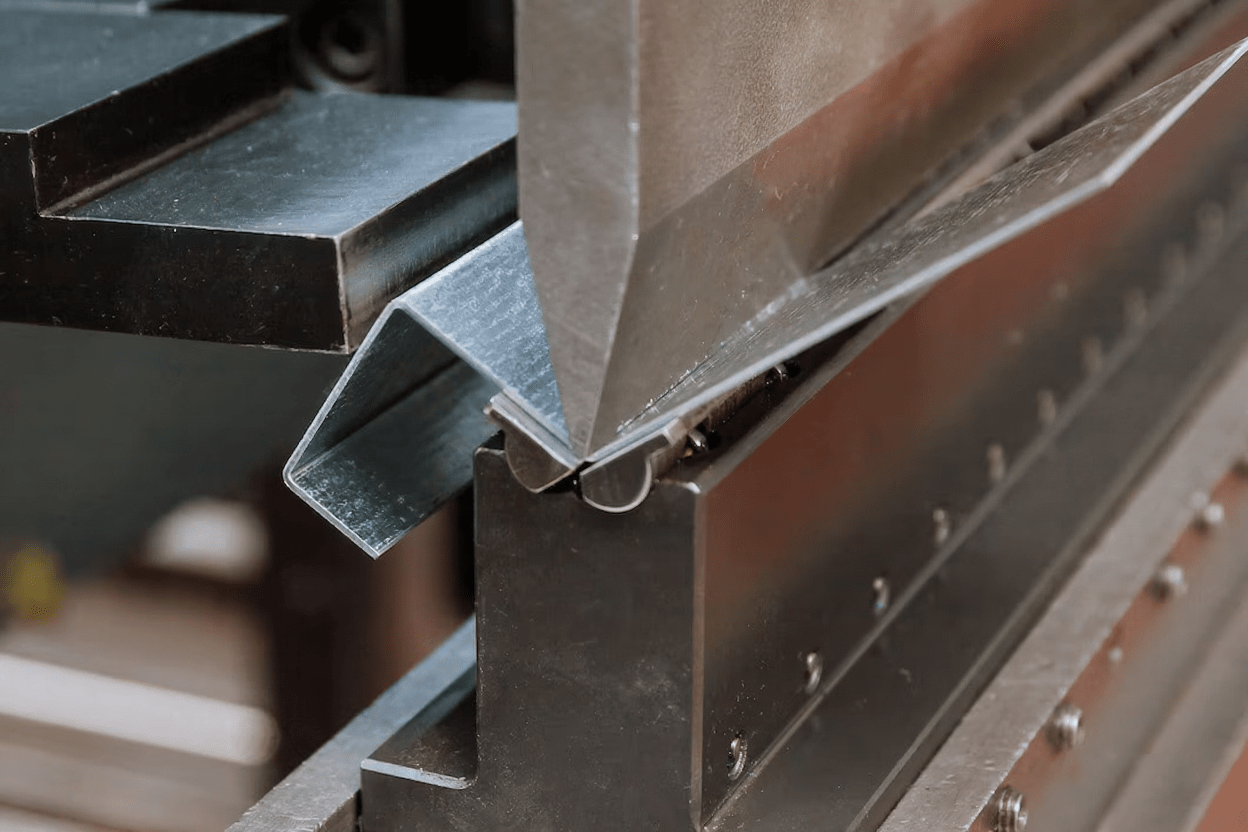

Press Tool Design

Our excellence lies in ensuring the demanded output, safe operation & easy maintenance by understanding the client’s products, production needs, and the infrastructure thoroughly. We bring about the best industry practices in designing, thus helping you function better.

Ready to Partner with US - Focused Mechanical Design Consultancy

📞 Work

with an India-based engineering team trusted by US manufacturers

📧 Request

a Free US Consultation — We work across US time zones and ensure full

IP protection.

Reverse Engineering

Want to grab a bigger market share than your competition with your product? Let our reverse engineering specialists work out outdated kinks from your system, and make your product more appealing to your customers. Our mechanical skills and tools help you in deducing your engineering problems. We use advanced digital engineering tools to identify design intent of products for a better, optimized product.

Value Engineering

Growing competition and changing trends can make products obsolete. We apply Value Analysis (VA) and Value Engineering (VE) to optimize features and reduce cost, and furthermore, bring the best outcome of your products. Let Engon boost your quality management, enhance resource efficiency, simplify procedures, and minimize overall paperwork at your organization.

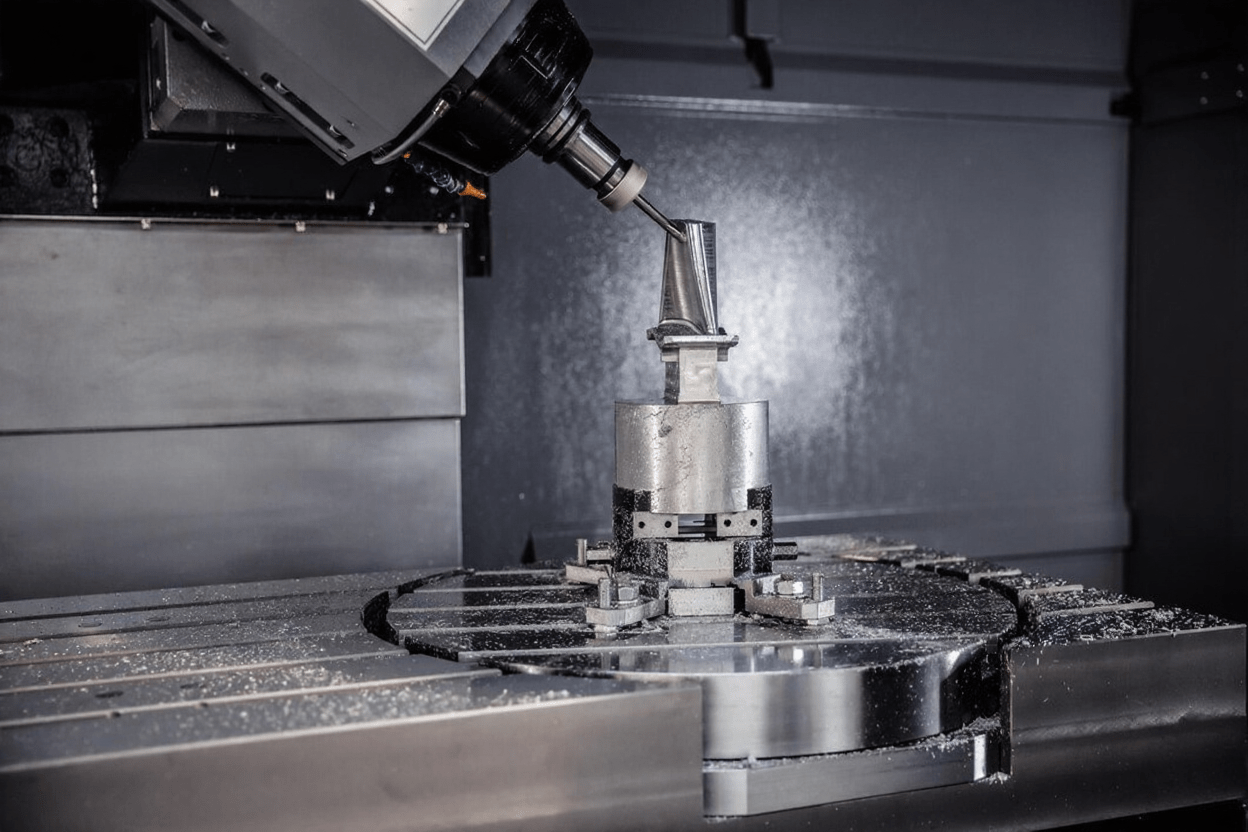

CNC Programming

Boost efficiency by using CNC machining using precise CNC programming for production, where parts are made with the highest levels of accuracy. Our specialists control machine tools with precision programming to support your manufacturing project. We focus on maximizing your output while minimizing the waste of time and materials. Let Engon optimize your 2D and 3D manufacturing operations.

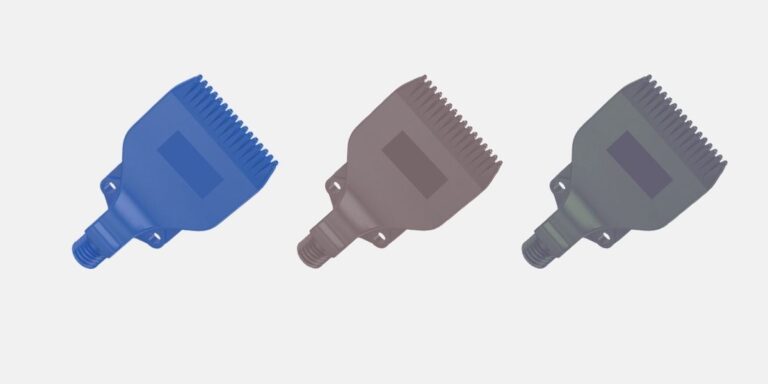

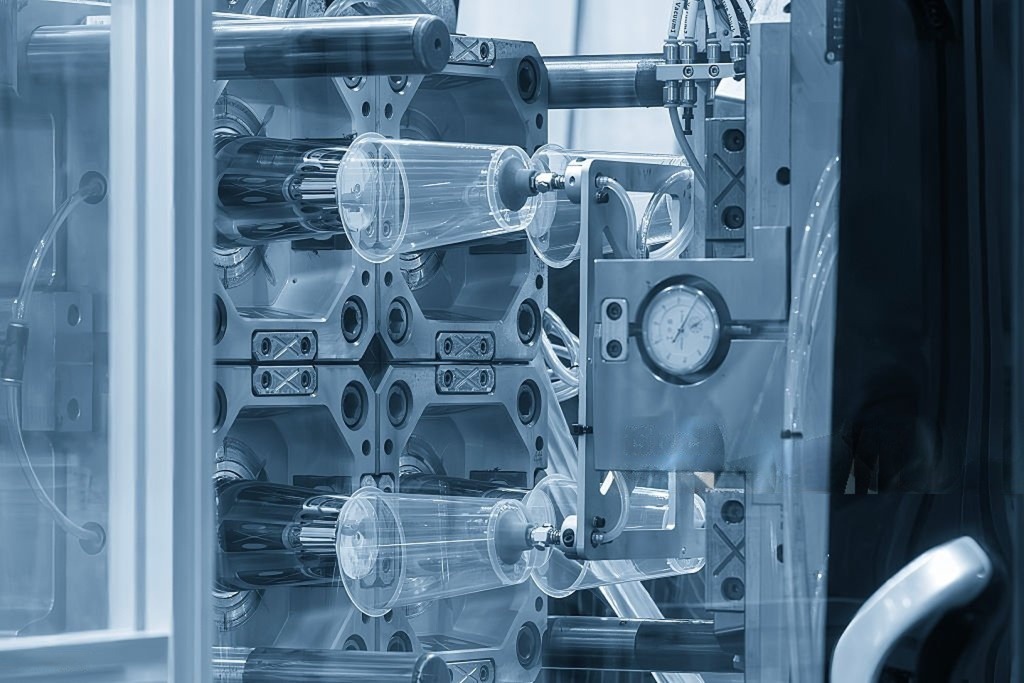

Plastic Product Design & Engineering

Bringing a product into the market involves a lot of intricacies, which you don't have to face alone. You need a partner who understands the end-to-end of Engineering and Design of plastics. We take complete ownership of the end-to-end design of plastic products for our clients. The right suggestion is critical to bring about value, and we are there to guide you all the way.

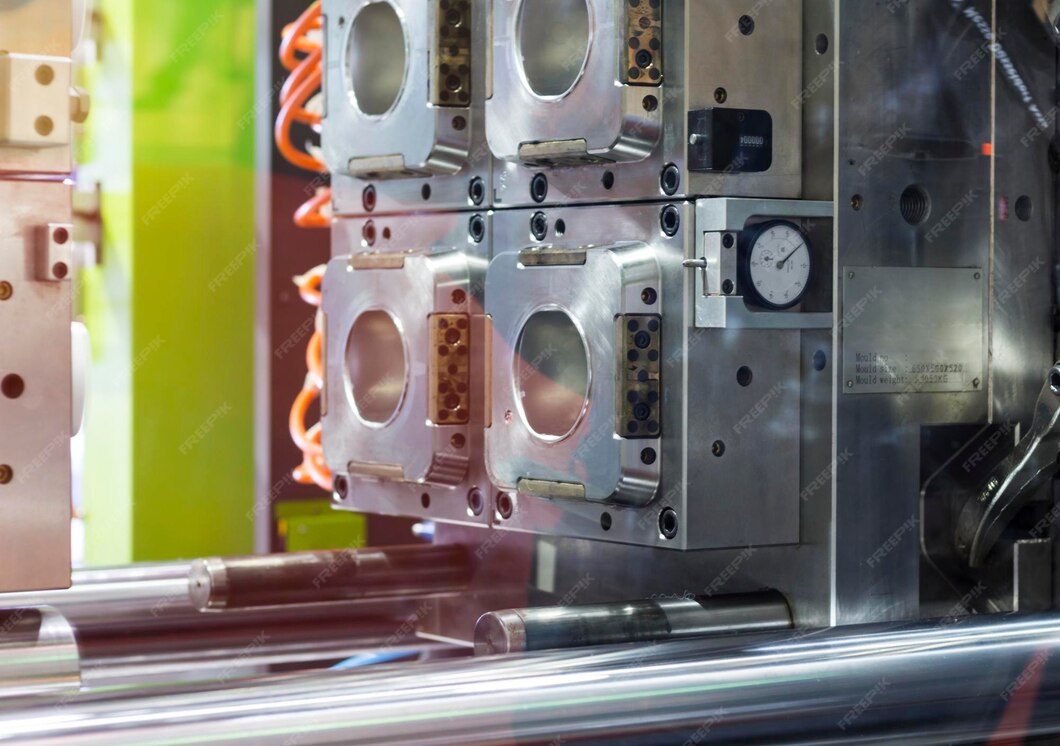

Mold Design

Tooling and mold design is a decisive part the success of your entire project. Our aim is to bring value by designing the kind of mold necessary for your manufacturing process, depending on your needs. The focus is on making the molds faster and more efficient. We prevent design and quality challenges before the molding process begins. Let Engon help you avoid costly end-use product failures.

Mold Flow Analysis

Plastics can be complicated, and molds required for your plastic products can get extremely costly and time consuming, thus leaving you with no scope for error. Being certain about the function will be the need of the hour. Hence, we deploy sophisticated technological tools to analyze and understand the outcomes. This way when a prototype goes into production, it performs and behaves optimally, right from the first time ever.

Jig & Fixture Design

Integrating jig and fixture design to your machining processes is always advantageous to your manufacturing project. Our designers help you meet the higher demands of your customers by providing more efficiency and precision to your manufacturing operations. Let Engon support you as a strategic partner and strong associate with our reliable jigs and fixture design services.

Sheet Metal Design & Engineering

Sheet metal design and engineering is a complex process, and needs to account a variation of parameters while designing to set the manufacturing right. We understand the typical issues of the manufacturers in applications and protect our customers from cost errors, while enabling high production rates for any sheet metal part or product.

As-built Engineering & Documentation Services

At Engon, we keep detailed records, in the form of as-built drawings and document markups as well as updating 3D models, drawings, and documents, to track the many changes from the original building plans that take place during a construction project. This helps spot and resolve issues in the changes before they become a problem.

Explore Our Case Studies

CAD design and drafting services

Our Top Industries

Outsourced Mechanical Engineering Services

Frequently Asked Questions – Mechanical Engineering Design Services

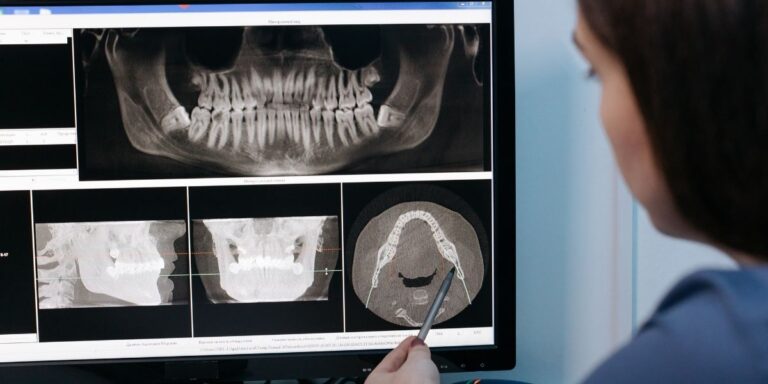

A: We provide mechanical engineering design services across multiple sectors, including industrial machinery design, automotive component design, consumer product development, and medical device engineering. Each project is customized to meet industry-specific standards, durability, and performance requirements.

A: Our mechanical product design projects vary in duration. Small CAD design projects or 3D modeling tasks can be completed in 1–2 weeks, while large-scale system designs requiring simulation, prototyping, and validation may take 6–12 weeks. Timelines depend on complexity and engineering requirements.

A: Yes. We offer end-to-end mechanical design services covering conceptual design, 3D CAD modeling, FEA analysis, rapid prototyping, and manufacturing support. Our prototype development process helps validate designs before full-scale production, ensuring cost-effectiveness and reduced time-to-market.

A: Unlike generic design vendors, we deliver custom mechanical engineering design solutions that combine innovation, precision, and manufacturability. Our team uses state-of-the-art CAD tools, FEA/CFD simulations, and 3D prototyping to ensure every design is optimized for performance, cost-efficiency, and durability. We also provide end-to-end support—from concept to production—making us a trusted partner for industries like automotive, industrial machinery, consumer products, and medical devices.

A: Pricing varies with scope, timeline, and expertise. Small or evolving tasks like CAD updates or simulations often use hourly billing, while clearly defined projects sre a fixed-price model. Companies needing continuous design or prototyping support often choose a monthly retainer, whereas large or complex product development is best managed with a milestone-based approach, where payments are tied to each phase from concept to prototype.

A: We use industry-leading CAD, CAE, and simulation software such as SolidWorks, CATIA, Creo, AutoCAD, and ANSYS to deliver high-precision designs. Our engineers also leverage rapid prototyping technologies and cloud-based collaboration platforms to accelerate mechanical product development services. This combination ensures accuracy, reliable analysis, and faster time-to-market for complex mechanical engineering projects.

A: We maintain a ready pool of experienced mechanical engineers supported by standardized workflows, enabling us to onboard projects within days. Our outsourced mechanical design services are powered by a modular delivery model, allowing us to start with a core team and quickly expand resources as project complexity grows. This approach ensures flexible scaling, cost efficiency, and consistent quality without delays.

A: Our communication model is transparent and collaborative from day one. Clients receive regular status updates, design previews, and simulation reports, along with direct access to our engineering team for quick clarifications. We prioritize alignment at every stage to ensure seamless execution of mechanical design and development projects across different time zones.

- Our design engineers bring deep expertise in tooling and manufacturing processes, ensuring Design for Manufacturability (DFM) principles are built into every project.

- We provide hands-on support during the tooling development stage, helping reduce rework, costs, and lead times.

- We recommend involving tool makers and production teams early in the design phase to identify challenges upfront, ensuring smoother transition from product design to mass manufacturing.

This approach helps clients achieve efficient, production-ready mechanical product designs that balance innovation, cost-effectiveness, and scalability.